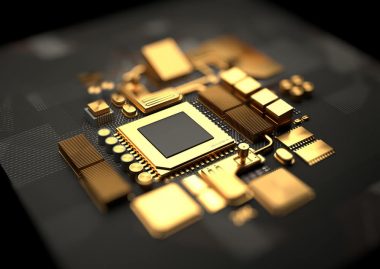

US firm Evotus is a precious metals recycling facility in North Carolina. The company says this expansion serves to recover more gold from discarded electronics.

A plant of Evotus in Raleigh recover ‘investment-grade’ gold from e-scrap via a chemical dissolution process. It raised around US$ 1.2 million to build a 15 000-square-foot facility, E-scrap News reports.

US firm Evotus is a precious metals recycling facility in North Carolina. The company says this expansion serves to recover more gold from discarded electronics.

A plant of Evotus in Raleigh recover ‘investment-grade’ gold from e-scrap via a chemical dissolution process. It raised around US$ 1.2 million to build a 15 000-square-foot facility, E-scrap News reports.

Initially, the recycling centre will handle computer processors or other components with over 1500 grams of gold per ton.

The plant about 500 pounds per day, running on one shift. Ultimately, it aims to recover up to 99% of the gold to produce bullion. According to company ceo Derek Ramsell, Evotus purchased technology from a leading European equipment provider.

The innovative process, which is also used in the mining industry, relies on acids in aqua regia to dissolve the gold. Then the material is exposed to sodium metabisulfite to precipitate the metal from the solution.

Recovering gold next month Ramsell says Evotus will install the equipment in next month. The company will be ready to start processing the first batch of e-scrap in late April or early May. The new site will be at full capacity this Summer, probably in July.

Evotus is currently exploring whether to send the other e-scrap metals to local refineries, or to install additional processing technologies for in-house treatment.

‘We’re a full-service domestic solution here in the US. We don’t ship anything at all overseas,’ Ramsell notes. ‘In addition to that, we’re providing a very sophisticated platform to easily communicate with our suppliers and streamline that value to them in a very easy-to-understand, very clear, streamlined, sophisticated process.’

Looking ahead, the entrepreneur reveals that his company is expanding the enterprise to 40 000-square-foot facility with a capacity of 30 tons per day. Such as large plant would take in a variety of feedstock-like printed circuit boards-to produce a number of metals.